Eugenia Kharlampieva, Ph.D., and Veronika Kozlovskaya, Ph.D., are chemists in the cargo business. Their vehicles are unusual—squishy balls and cubes—and they are tiny. In fact, 10 could park side by side across a human hair. But these “microcapsules” could become a driving force in human and environmental health. A few million could deliver enough high-powered medicine to kill a tumor. Or smuggle life-saving islet cells into a patient with type 1 diabetes. They can even be deployed in water to eat up oil spills.

Microcapsules are a big deal these days, say Kharlampieva, an associate professor in the UAB College of Arts and Sciences Department of Chemistry, and Kozlovskaya, a research scientist and longtime collaborator in her lab. Scientists everywhere are building them and figuring out how to harness their potential.

But a hard journey lies ahead for micro-capsules in the human body. The vigilant immune system and turbulent bloodstream can destroy or eject them from the body before they can deliver their precious payloads. So Kharlampieva and Kozlovskaya are leading the charge to create controlled, “intelligent” microcapsules that can transform to evade obstacles and transport drugs to precise targets.

Common bonds

The two researchers already know a thing or two about transformation. The friends share a hometown—Chelyabinsk, in central Russia—and both earned master’s degrees in organic chemistry. But once they started working in industry, they felt unfulfilled and began looking for new challenges in a completely different field. “Veronika suggested we start learning languages,” recalls Kharlampieva. A few years later, both women had earned degrees in linguistics and were planning new careers, when Kharlampieva’s mentor in organic chemistry told her about a graduate position in the United States. She wasn’t interested, but he called her bluff. “He said, ‘You want to be a great linguist. How about practicing your English?’”

Kharlampieva decided to try it for a year and ended up falling in love with chemistry all over again at New Jersey’s Stevens Institute of Technology. When her lab needed more graduate students, Kharlampieva convinced Kozlovskaya, who had been teaching in Russia, to join her in Hoboken.

The experience put them on the road to working with microcapsules by making them experts in polymer chemistry. Like rows of cookie-cutter apartment buildings, a polymer is a molecular chain of repeating units. Some polymers are natural, such as rubber. But the real interest in the field is in lab-created polymers, which can be designed to incorporate a variety of useful properties.

Eugenia Kharlampieva checks a solution of iron oxide microparticles that can be used to make nonspherical hydrogel capsules.

Eugenia Kharlampieva checks a solution of iron oxide microparticles that can be used to make nonspherical hydrogel capsules.

Smooth moves

Kharlampieva’s UAB lab has pioneered a layer-by-layer technology that produces hollow microcapsules made of novel polymer hydrogels. The protective coating helps the capsules safely stow their cargo until they reach their destination. By using different chemical ingredients in the hydrogel, the researchers can add unique features that make the balls and cubes ideal vehicles for delivering therapies.

Smooth outer shells, for example, prevent immune-system sentinels from planting protein warning signs on the capsules, so they avoid being tagged as foreign and destroyed. And while most synthetic particles are flushed out of the bloodstream within minutes. the researchers have designed microcapsules that survive for hours. They also have improved their aim, designing capsules that break down at a specific acidity level, meaning they hold onto their payload until they reach the highly acidic environment inside cancer cells.

Another type of capsule can be tracked through the body using ultrasound imaging. Once the tiny bubbles congregate in a tumor, a higher dose of ultrasound can trigger the microcapsules to rupture and release cancer-fighting drugs. Kharlampieva says the technique could one day benefit patients with breast, melanoma, colon, prostate, or lung cancer by providing an effective alternative to surgery that spares healthy tissue. Other microcapsule variants can carry antioxidant compounds, which scavenge molecules that damage cells in diseases including diabetes, atherosclerosis, Alzheimer’s disease, kidney disease, and cancer. One day, the hydrogel coating might help ward off immune-system attacks against insulin-producing cells transplanted into patients to treat type 1 diabetes.

While the hydrogel gives the capsules strength and stealth, it also makes them soft and elastic enough to slip through tight spaces. That flexibility is an important advantage and mimics the shape-shifting powers of the body’s own biological systems. “Look at red blood cells,” Kharlampieva says. They carry oxygen throughout the body, even traversing capillaries much smaller than themselves, she explains. “They can squeeze into the vasculature and then recover their shape as they pass through.”

To move these discoveries from the lab to the clinic, Kharlampieva has forged collaborations with colleagues across UAB, including School of Medicine scientists focusing on cancer and diabetes. These research teams study the safety and effectiveness of the capsules. So far, findings show that the bubbles are nontoxic and safely broken down or excreted from the body over time.

Spill science

Another UAB-created polymer vehicle might help disperse future oil spills like the Deepwater Horizon disaster, which leaked 210 million gallons into the Gulf of Mexico soon after Kharlampieva and Kozlovskaya arrived in Birmingham in 2010. Their solution: self-destructing microsponges that absorb oil and harness the sun’s ultraviolet rays to degrade it into carbon dioxide and water. When the job is done, the particles themselves degrade as well.

Kharlampieva holds a patent on the technology, which has already been licensed to industry and may soon generate a spin-off company. “There are other technologies out there that can absorb oil, but they need to be disposed of afterward and can be highly toxic,” she says. “Our material is nontoxic and cleans up after itself.”

Veronika Kozlovskaya (right) observes Nirzari Gupta, a chemistry Ph.D. student, as she prepares solutions for making nonspherical copper oxide microparticles.

Veronika Kozlovskaya (right) observes Nirzari Gupta, a chemistry Ph.D. student, as she prepares solutions for making nonspherical copper oxide microparticles.

Bubbling with enthusiasm

Kharlampieva and Kozlovskaya are enthusiastic champions of their discipline, sharing their excitement and discoveries with graduate students, undergraduates, and even local high-school students, who sometimes volunteer in the lab. Everyone is eager to learn, says Kharlampieva, who restarted and expanded polymer chemistry courses for undergraduates when she came to UAB. “The fact that my class has increased its enrollment from the time I started teaching it motivates me,” she notes. Her lab also provides “constant” opportunities for undergraduate researchers, she adds.

The thrill of the work is infectious. “We’re mimicking nature,” Kozlovskaya says. “We study how nature does it. Then we ask if we can do the same thing—and can we make it better?”

All signs point to yes, and the microcapsule breakthroughs prove it. “Polymer chemistry is changing the world,” Kharlampieva tells her students. “You can be part of it.”

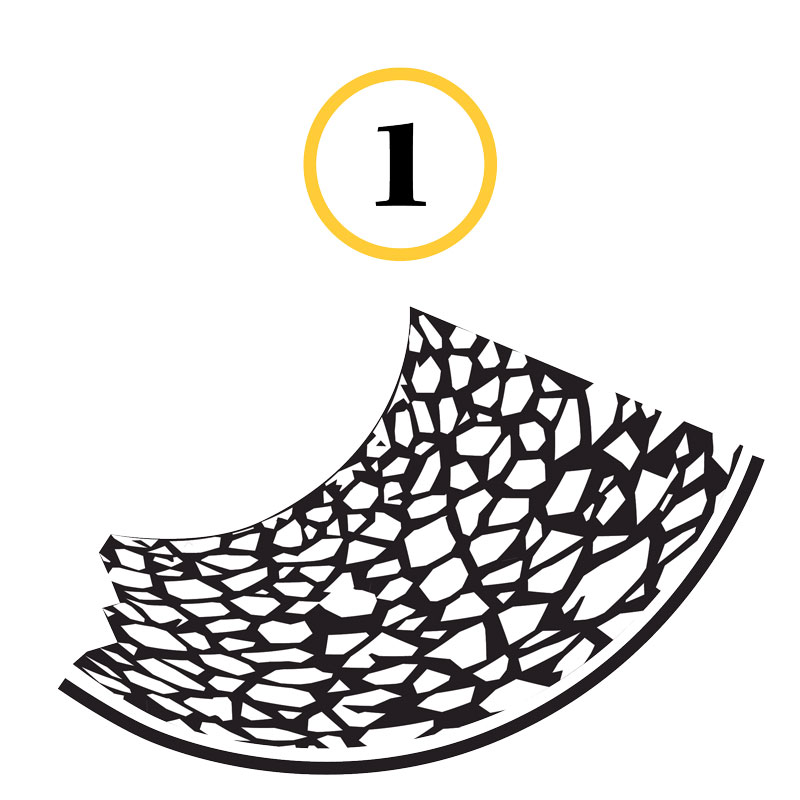

Place the cores in a solution of doxorubicin, a potent anticancer drug, which they will soak up like a sponge.

Place the cores in a solution of doxorubicin, a potent anticancer drug, which they will soak up like a sponge. Add several tannic acid/polymer layers to create a microcapsule shell.

Add several tannic acid/polymer layers to create a microcapsule shell. Dissolve the core in hydrofluoric acid and purify in phosphate buffer solution.

Dissolve the core in hydrofluoric acid and purify in phosphate buffer solution. Inject into the bloodstream. The microcapsules will disintegrate in the acidic environment of cancer cells and deliver their payload.

Inject into the bloodstream. The microcapsules will disintegrate in the acidic environment of cancer cells and deliver their payload.