A UAB initiative to reduce expenses and lower the university’s impact on the city stormwater system proves water-conservation projects can be feasible and cost-effective.

A UAB initiative to reduce expenses and lower the university’s impact on the city stormwater system proves water-conservation projects can be feasible and cost-effective.

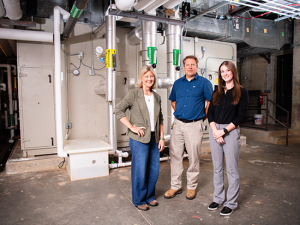

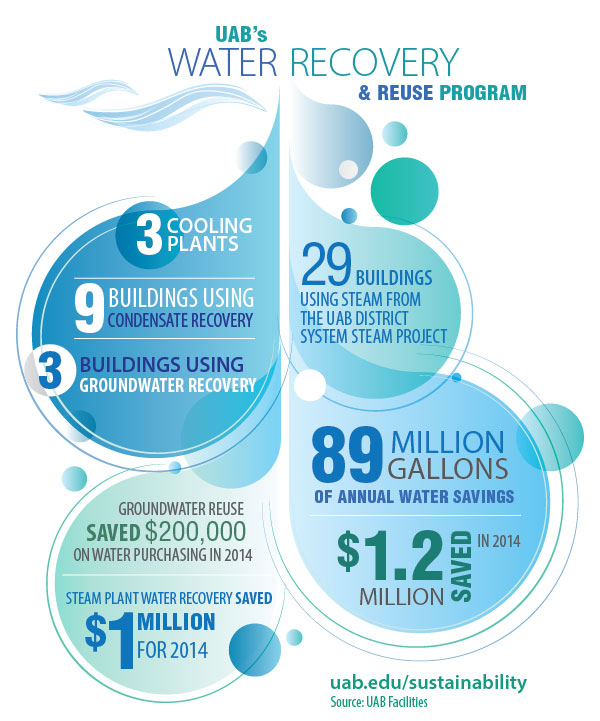

In 2014, UAB’s Water Reuse and Recovery Program, which uses a network of tanks and piping to capture and reuse groundwater and condensate from heating and cooling systems, saved about 89 million gallons of water and $1.2 million, says Matt Winslett, engineering manager of Energy Management in UAB Facilities. That’s a commendable feat — one the Cahaba River Society rewarded with its annual Watershed Conservation Development Award this past month.

“This clever combination of recovery and reuse of groundwater, cooling-system condensate and heating-system condensate will save enormous amounts of water and energy well into the future,” said Beth Stewart, executive director of the Cahaba River Society. “This is exactly the type of forward thinking CRS seeks to recognize, and we congratulate UAB for their commitment to water sustainability and stewardship.”

“UAB is very honored to receive this award from the Cahaba River Society,” Winslett said. “We take our part in maintaining the sustainability of the local environment very seriously.”

How does this work?

UAB has three central cooling plants and multiple cooling towers that are linked via a network of underground piping. Water from these plants is cooled to 45 degrees Fahrenheit. The heat is removed from the water through evaporation within the plant’s cooling towers, and the water is then piped into buildings to provide air conditioning.

|

Related Links: UAB’s new steam system will save energy, dollars |

Afterward, the water — now warmed to about 55 degrees Fahrenheit — creates condensate that forms on the air handler coils as it leaves the buildings. For years the condensate had been collected and discarded into a nearby stormwater drain.

UAB’s program enables the condensate to be collected, filtered, cleaned and pumped across town to UAB’s district chilled water plant’s cooling tower through the underground chilled water-return line. This both conserves water use and reduces the volume of municipal drinking water that must be purchased for cooling. The cold, mineral-free, distilled water also contributes to less water treatment costs as well as the input energy required in the cooling process.

Savings from the condensate-collection system pay for the investment in three years on average, and improvements for the groundwater systems pay for themselves in less than a year, Winslett said.

“We are so proud to be a part of an organization that allows us the creative freedom and budget to identify and implement projects that make these positive efforts in water recovery and reclamation,” Winslett said. “I look forward to even more in the future.”